Sleipner E400 Delivery, Training & Commissioning

client

Barrick Gold

location

Lumwana, Zambia

Services delivered

Supply & Training

We successfully supplied and delivered a Sleipner E400 to Barrick Lumwana, followed by structured on-site support and maintenance training for the site team. The project focused on ensuring safe, correct equipment handover and building operator/maintainer capability from day one.

Sleipner’s ingenious, robust and mine-proven mobility solutions help you increase productivity and reduce costs. With Sleipner dollies and trailers, you can achieve up to an 85% reduction in transport times for tracked equipment compared to driving on tracks. Sleipner dollies and off-road trailers also significantly reduce the maintenance costs of the tracked equipment by doubling or even tripling the lifespan of the undercarriage.

The Challenge

Barrick Lumwana needed a deployment partner who understood that successful commissioning starts before the machine arrives and continues well after delivery. Their requirements were:

Safe, compliant delivery integrated with existing site procedures

Commissioning readiness with thorough inspection, functional verification, and complete documentation

Knowledge transfer to build internal maintenance capability and ensure sustained uptime

Our Approach: Delivery and Capability

We designed a structured two-day engagement that combined equipment handover with practical skills development, ensuring the Barrick Lumwana team could confidently operate and maintain their Sleipner E400 from day one.

Day 1: Safe Delivery & Commissioning Handover

The first day established the foundation for successful operation:

Site induction and safety alignment with Barrick protocols

Formal delivery confirmation and equipment walkthrough

Pre-commissioning inspection and readiness verification

Operator familiarization session covering key operational features

Collaborative Q&A with operations and maintenance stakeholders

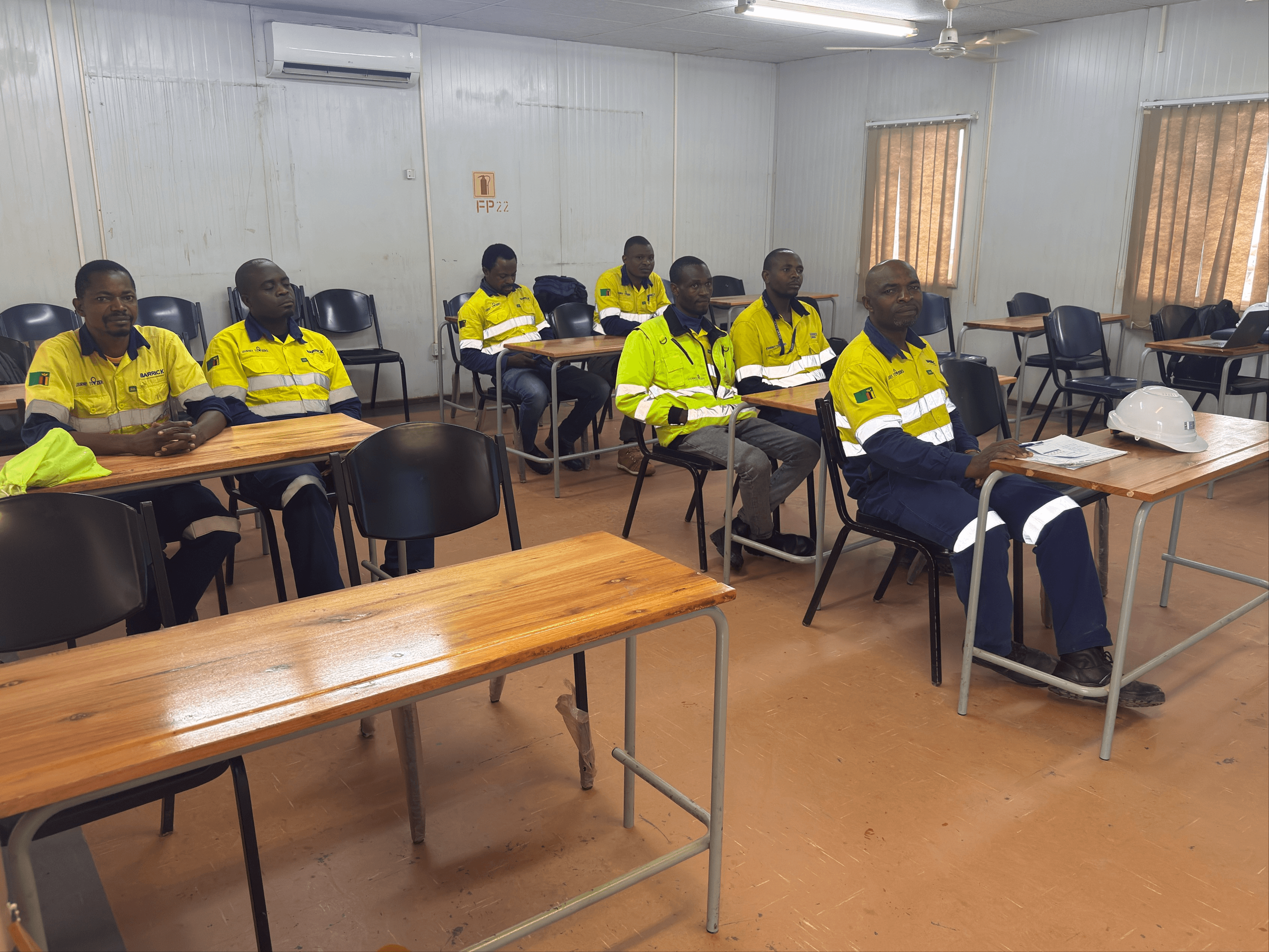

Day 2: Maintenance Training

Day two focused on building practical maintenance competency through site-relevant training:

Routine care: Inspection points, service intervals, and preventative maintenance schedules

Operational safety: Pre-start procedures and critical operating checks

Troubleshooting fundamentals: First-check protocols and common failure point recognition

Best practices: Operator do's and don'ts, escalation procedures, and safety protocols

Documentation: Maintenance logging standards and recommended formats

Ready to discuss your next deployment?

Contact us to learn how we can support your commissioning and training needs.